Do you know that when we bend a sheet metal piece, the total length of the bent component is always more than the length of the unfolded or flat sheet?

And, another interesting thing is that when you want to create a sheet metal component, you just know the size or dimensions of the final bent component. Then how will you calculate the size or length of the flat pattern?

As you know, for the companies that offer sheet metal fabrication services, the first step in the process of creating a sheet metal component is to create a flat pattern of the exact size which will be bent into the final component of accurate size.

Then how will you create that flat pattern or unfolded sheet, if you don’t know its size which is different from the size of the finished component? Here the role of Sheet Metal bend Allowance comes into the picture.

Bend Allowance and Bend Deduction both values can be used to calculate the size of the flat pattern. But in this article, we will just cover the first term.

Sheet Metal Bend Allowance

When a piece of sheet metal goes through the process of bending, its upper layer (with inside radius) is compressed and the lower layer (with outside radius) is stretched. Due to this tension and compression, the length of the sheet metal piece increases.

We have to consider this increase in length (during bending) while forming or producing a flat pattern for the final component.

The extra length that we need to add to the total length of the legs of the finished component in order to get the length of the flat pattern is called the Bend Allowance.

And, Bend Allowance is always equal to the length of the arc of the bend, measured along the neutral axis. Just like Bend Deduction and K-factor, It is also a very important term in sheet metal fabrication.

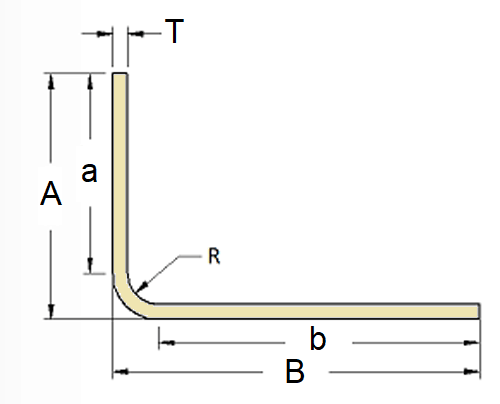

As shown in Fig.1, ‘A’ and ‘B’ are the flange lengths of the sheet metal component. On the other hand, ‘a’ and ‘b’ are the respective leg length. The thickness of the sheet is indicated by ‘t’.

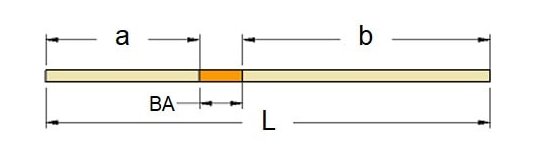

In the other figure, as you can see below, Bend Allowance is BA. The required length of the flat pattern is ‘L’.

As you can see here in the above figure, Bend Allowance is the difference between the total length (L) of the unfolded sheet (flat pattern) and the sum of the lengths (a+b) of all of the legs of the finished component.

So what do you understand from this? Put gentle pressure on your mind and think about it. It’s quite clear. Let us explain it…

When you want to fabricate or form a sheet metal component, if you have the length of the legs, you can easily calculate the size/dimension/length of the flat pattern. We hope you get the point.

So this is the application or use of the Sheet Metal Bend Allowance. But now the question that may strike your mind is how to calculate this Allowance. Don’t worry, now we are coming to the same point.

Bend Allowance Calculator

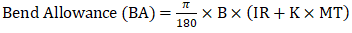

It is very easy to calculate Bend Allowance if you have a formula for it. Below we have shared that formula. You just need to have the values for some required variables like Bend Angle, Inside Radius, K-factor, Material Thickness, etc.

If you have these required data, you can simply put it in the formula and calculate this Allowance with this Bend Allowance Calculator.

Bend Allowance Formula

The bend allowance can be easily calculated by using the formula given below:

Here, B = Bend Angle in degree,

IR = Inside Radius

K = K-factor (It is different for different materials and depends upon the physical properties)

MT = Material Thickness

[Note:- The bend angle is not the included angle. It is the excluded angle actually]

And, if you don’t want to use this formula and don’t want to calculate the Allowance again by again, you can use the Bend Allowance Chart also.

This chart displays the value of BA for different Bend Angles, different bend radii, different Material thicknesses, etc. You can check the related value as per your data.

So, this was all about the Bend Allowance of Sheet Metal. If you have any doubt/query still striking in your mind regarding this topic, you can shout in the comments below. We will be there to help you to the best level possible for us.

Here are some other recommended articles for you to read next:

![Sheet Metal Bend Allowance Explained [with Formula and Calculator] Sheet Metal Bend Allowance](https://guidebytips.com/wp-content/uploads/2019/06/Sheet-Metal-Bend-Allowance-Explained-with-Formula-and-Calculator-696x392.jpg)