In our previous post, we discussed the Bend Allowance (BA). In today’s post, we are going to discuss Bend Deduction. Just like BA and K-factor, Sheet Metal Bend Deduction is also a very crucial part of sheet metal design terminology.

First of all, let us explain why and where you need to use this Bend Deduction.

Suppose that you have designed a sheet metal component for fabrication. And, you have all the dimensions of the final component in your design.

This is not enough for the fabricator to fabricate your component. He will have to create a flat pattern first. After that, he will make all the forming operations, whether it is punching, bending, or any other.

If you just provide the design of the final component, it will not be possible for the fabricator to create or produce a flat pattern for your component. Then how will he fabricate the final component?

So our point here is to establish the fact that it is necessary to design the flat pattern also along with the design of your final or finished component.

And, the interesting and surprising thing is that the total length of the bent sheet is always greater than the length of the unfolded piece of the sheet. In other words, you can say that the total length of the flanges of the bent sheet is always greater than the length of the flat sheet or flat pattern.

The reason behind this is that the material along the bend undergoes deformation (stretched and compressed) when you bend it. It means that you can not just use the length of your final component in your design of the flat pattern for that component.

Then how to calculate the exact length of the flat pattern that will give you the required flange length in the final component?

Here comes the role of Bend Deduction. You can calculate the length of the flat sheet by deducting or subtracting Bend Deduction from the total length of flanges of the finished component.

[Note:- The length of the flat pattern can be calculated by BA also as we mentioned in our previous post.]

What is Bend Deduction

Bend Deduction is the measurement of the length that you will have to deduct from the total length of the flanges of the final sheet metal component in order to get the correct length of the flat pattern that you need to create for that component.

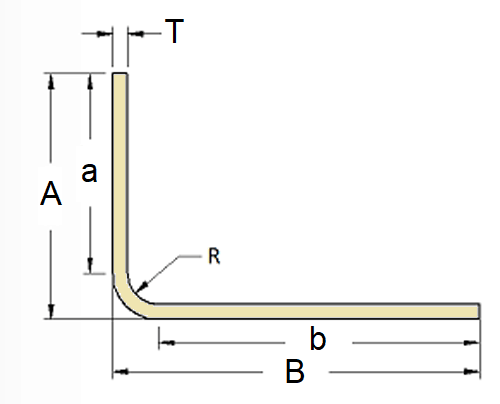

As you can see above in Fig.1, ‘A’ and ‘B’ are the flange lengths of the final component. ‘a’ and ‘b’ indicate the leg lengths of the component. ‘T’ indicates the thickness of the sheet. And, ‘R’ is the inside radius of the bend. The Inside Radius is generally equal to the radius of the bending tool.

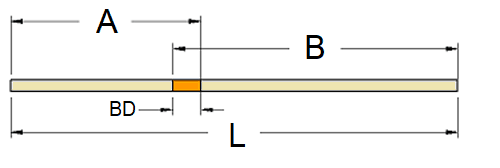

In Fig.2, you can see the Bend Deduction (BD) indicated with the orange color. ‘L’ is the length of the flat pattern of the finished component. This figure clearly indicates that the length of the flat pattern (L) is equal to the difference between the sum of the flange lengths (A & B) and the value of the Bend Deduction (BD).

Now the question is how to calculate this value of BD. Now we are coming to this point. You can calculate this value for different values of the available parameters (Sheet Thickness, Bend Angle, Inside Bend radius, etc.) Keep reading…

Bend Deduction Calculator

Bend deduction can be easily calculated if you have a formula for it. Below I have shared that formula. You just have to collect some required data like K-factor, sheet metal thickness, bend angle, and inside radius of the bend.

If you have the values of these variables, you can simply put them in the formula and calculate the final value by using this Bend Deduction Calculator.

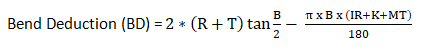

Bend Deduction Formula

Bend Deduction (BD) = (2xOSSB) – BA

Here, OSSB = Outside Set Back

BA = Bend Allowance

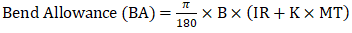

And, as we know that the formula for calculating BA (as we explained in this post) is

And, the formula for Outside Set Back is

Hence,

So this is the final formula to calculate the Bend Deduction.

Here, R and IR (Both are the same) = Inside Bend Radius

T = Sheet Thickness

B = Bend Angle

K = K-Factor (It is different for different materials and depends on the physical properties of the material)

MT = Material Thickness or Sheet Thickness

[Note:- Bend Angle is not the included angle. It is actually the excluded angle.]

If you don’t want to calculate this value by yourself, you can also use a ready-made Bend Deduction Chart. This chart will provide you with BD values for different values of all of the parameters.

Bend Deduction Chart

Bend deduction and bend allowance can be mixed up by beginners however good to differ fastly. Once an individual is clearly able to differentiate between these two phenomena, creating flat patterns in sheet metals becomes a piece of cake.

Bend deduction charts speed up this process by providing an already calculated set of figures which negates the need to carry out individual calculations. A bend deduction chart is a good starting point.

However, there are individualistic needs of metals depending on the type of alloy they are, the product to be made, the thickness of the metal, the type of finishing needed, etc; take into account these idiosyncratic demands while calculating bend deduction.

Conclusion

What would you prefer for the calculation of the length of the Flat Pattern, BA, or BD? What is your opinion? Tell us in the comments below.

So, this is all about today’s topic. We hope you got all the points we mentioned above. If you are still struggling to understand anything, please allow us to know that as well in the comments below. We will try to respond as soon as possible.

We have some other articles for you to read next:

![Bend Deduction Explained [With Formula and Calculator] Bend Deduction](https://guidebytips.com/wp-content/uploads/2019/06/Bend-Deduction-Explained-With-Formula-and-Calculator-696x392.jpg)