Sheet Metal is a vital part of our daily life. Many parts and types of equipment using sheet metal are there in electronics, aerospace, HVAC, and almost all the fields.

Sheet metal fabrication is the process of converting sheet metal stock into the final sheet metal product for use in various applications. This process may vary from case to case depending upon the requirement of the design specifications of the final sheet metal product.

However, there are some general steps in a typical sheet metal fabrication process, which we have explained below. Before we start with that, let’s first deeply understand what sheet metal fabrication is.

Table of Contents

What is Sheet Metal Fabrication?

Sheet metal fabrication, as the name suggests, is a process in which flat metal sheets are restructured into different shapes or products using procedures like cutting, bending, and stretching.

Sheets of metals are given shapes that ultimately become products by applying heat, pressure, or tools like band saws and press brakes on them.

Metal objects like home appliances, crockery, and medical appliances like syringes, plumbing, computer parts, military objects, and construction materials are made using sheet metal fabrication.

Industrial development has helped in easing the processes that are required in the process of metal fabrication. For example, engineering developments have made the process of welding, punching, bending, and stretching metals easier and much safer.

Metals are everywhere, and most industries are heavily dependent on products made from them. Here are industries that depend on products made using sheet metal fabrication:

- Farming

- Railways

- Medical industry

- Pharmaceuticals

- Plumbing

- Kitchen Appliances

- Aerospace

- Computer

- Automobile

- Military

- Telecommunications

- Construction

Sheet Metal Fabrication Process Steps

The following 8 steps are involved in a typical Sheet Metal Fabrication Process:

Step-1: Design and Drawing

The first step in the process of sheet metal fabrication is to create a design for the final product. In case you are a sheet metal manufacturing company and are manufacturing the sheet metal product, not for yourself but for a client, the design or a rough design idea will be provided by your client in most cases.

This is the case with most of the companies which are manufacturing sheet metal products as an OEM (Original Equipment Manufacturer) for their clients. Such companies or industries may not consider the designing process as a part of their fabrication process.

For creating the design of a sheet metal product, we first need to create a blueprint. That blueprint helps in creating a rough design of the final product. On the basis of that rough design, the final design & drawings in which all specifications are indicated are created to be used for manufacturing the final sheet metal product.

Step-2: Blank-Cutting

Sheet metals are produced in large coils. Those coils are then cut into the desired length to create the small-length rectangular sheets. Further, the manufacturers of these rectangular sheets supply them to the sheet metal fabrication industries for their use.

Blank-cutting is the 2nd step in the fabrication process and it is the process of cutting flat sheet metal blank out of a large sheet. The blank size is according to the requirement of the final product’s design.

Shearing Machines are generally used for cutting sheet metal blanks. Laser cutting, water jet cutting, and plasma cutting are some more precise and advanced methods for cutting.

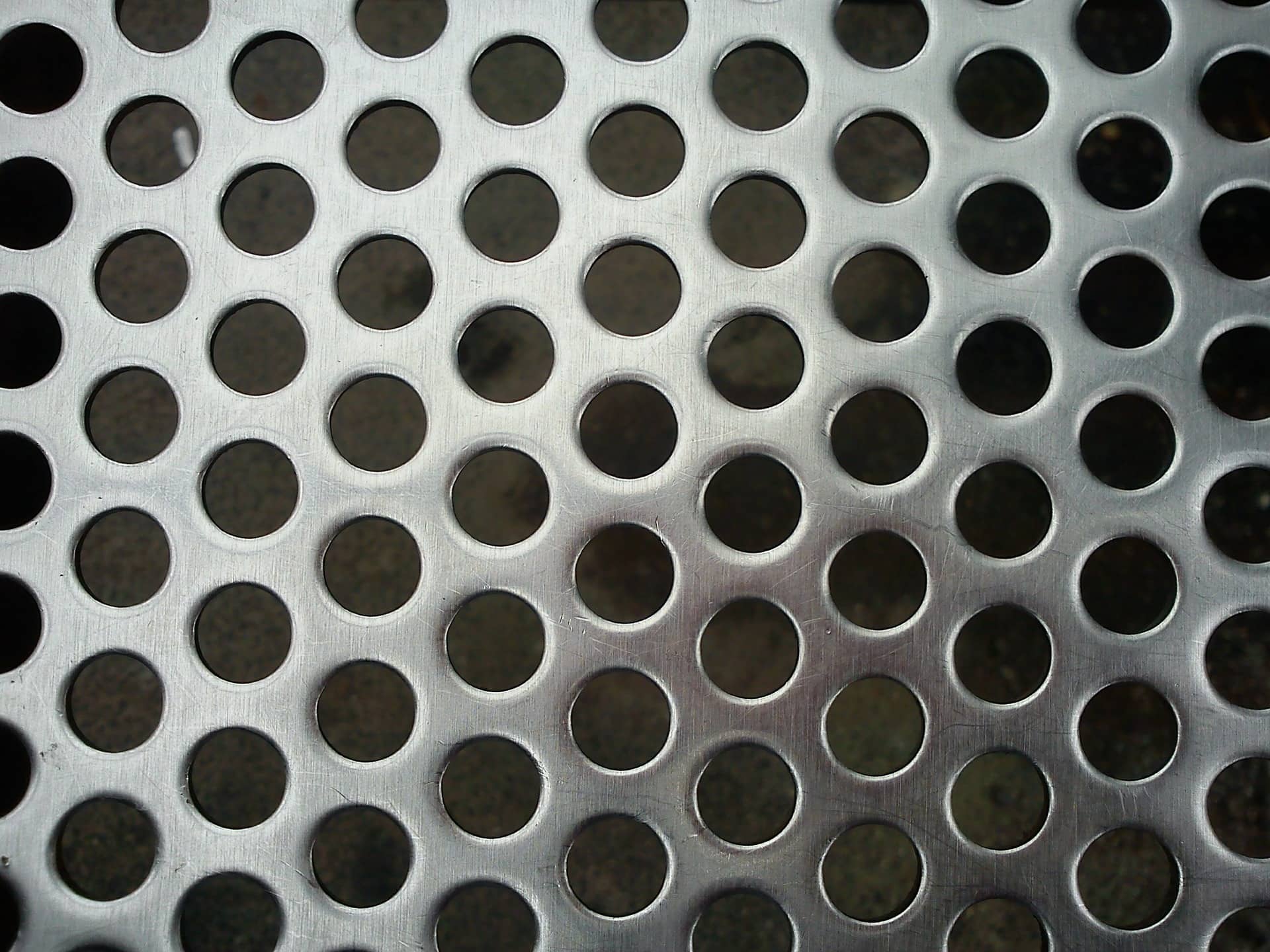

Step-3: Punching

After the sheet metal blank has been cut into the required size, the next step is “punching” in the fabrication process.

When it comes to punching operation, it is performed to produce holes of different designs and shapes in the sheet metal blank. This operation is generally performed with the use of Punching Machines.

In some cases, laser cutting technology is also used with the purpose of getting optimum precision.

Step-4: Bending

The next step in the process is bending. Sheet metal is bent at various places and angles as per the requirement of the design specifications. These bends are made in a sequence that any of the bends may not make any hurdle in the execution of the next bend.

The machine that is generally used to perform this task is called a press brake.

Step-5: Assembly of Components

After all of the components (of the final sheet metal product) have been created by performing the above-mentioned operations, then the 5th step comes. This step involves the assembly of all of the components.

Most of the time, welding is performed to assemble the sheet metal parts. In some cases, other options like adhesive bonding, riveting, etc are also used for assembly. CO2 welding and spot welding are some of the welding options that are made use of in the assembly of sheet metal parts.

Step-6: Finishing of Final Product

After the assembly of sheet metal parts, the final product is sent for the finishing process. Finishing is done to provide a required appearance as well as other desired physical properties as per the requirement.

It may be a simple cleaning. It may also include some other processes like coating, painting, galvanizing, etc. Some special heat treatments may also be performed to provide some special properties needed for the product to survive in a special working environment.

Step-7: Quality Control

After performing all of the steps to produce a sheet-metal product, the final product is now checked to ensure optimum quality. All specifications are verified to match exactly the given design.

If any error is observed, the piece is rejected and sent back for correction. The quality of finishing is also verified. If the quality is found OK from all aspects, the piece is cleared for “packing” (the next in this process).

Step-8: Packing & Shipping

Next comes the last step in the fabrication process. The final product is packed and shipped to the client or the place of its use.

So these were the 8 steps that are generally involved in the process of sheet metal fabrication.

Sheet Metal Fabrication Techniques

The various sheet metal fabrication techniques are as follows:

- Cutting metal: Water jets, torches, or saws are used to cut metal sheets that further make products.

- Bending metal: Metal brakes or form benders are used to bend metal sheets at different angles and create unique bends and edges.

- Welding: Welding is the most commonly used sheet metal fabrication technique. Depending on the kind of material and its thickness, different welding equipment is used.

- Shrinking: Metal is also shrunk to give the shapes of products. Shrinking is done using heat, tucking forks, or shrinking machines.

- Stretching: To make very sleek or delicate metal products, stretching is required and is done through equipment like English wheels, hammers, anvil, and professional stretcher machines.

- Finishing: After an appropriate metal fabrication technique is used and the desired shape is obtained, the metal is given finishing touches like removing abrasive edges, buffing, and coating using preventative materials.

We hope you enjoyed reading this article from start to end. If you think it was really full of knowledge and worth sharing, please share it with others also. You can share it with your friends on social media platforms, using the social sharing buttons given below.

If you have any doubts about the topic explained above, please use our comment section below to discuss it. We will reply and try our best to assist you.

Below we have shared some other related articles for you to read next: