A milling machine is an important tool in any workshop, providing a wide range of capabilities that can come in handy.

It can help you to cut, sand, and shape a piece of metal without needing to look at a reference object in the lab to follow along. They can also allow you to perform impossible operations with simple hand tools alone.

But what exactly is a milling machine, and how can it be used for good? This article will explore everything you need to know about this tool to get the most out of it.

Let’s dig in!

[PS: You should also check out our article on Shaper Machine and Different Types of Shaper Machines]

What is a Milling Machines

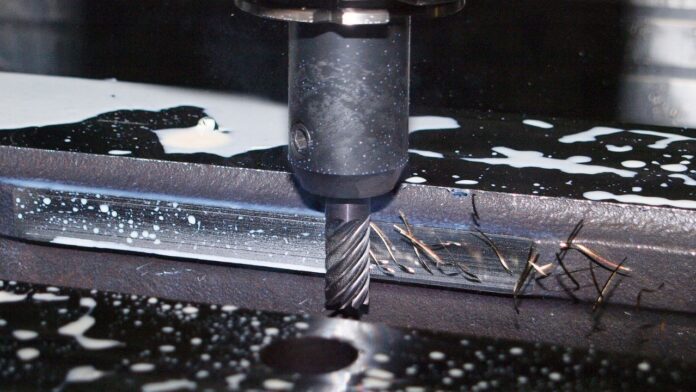

A milling machine is a machine tool that uses cutter tools to remove material from a workpiece. It is operated by a computer numerical control (CNC) system that controls the direction and speed of the cutter.

The workpiece is usually mounted on a table that can be moved in the X, Y, and Z axes.

The History of Milling Machines

Milling machines have a long and rich history dating back to at least the early 1800s. Their most basic form has been used to Sharpen two flat surfaces by removing material from one or both surfaces.

And the first milling machine was likely developed in the early 1800s by a man named Eli Whitney. He was a prolific inventor and is also credited with inventing the cotton gin.

These machines have come a long way since their early days and will likely continue to evolve as technology advances.

Different Types of Milling Machines

Milling machines are classified into two basic types: horizontal and vertical. Each type has its own advantages and disadvantages, so choosing the right type of milling machine is critical to getting the job done efficiently and correctly.

-Horizontal Mill

Horizontal milling machines have the spindle mounted in a horizontal position. This means that the cutting tools can be positioned at various angles, allowing for more versatility and flexibility when milling.

However, horizontal milling machines are generally more expensive than vertical milling machines.

-Vertical Mill

Vertical milling machines have the spindle mounted in a vertical position. It means that the cutting tools are positioned vertically, making them more suitable for tasks that require precise cuts and drilling.

However, vertical milling machines are less versatile than horizontal milling machines.

-Universal Mill

You can use this machine for various milling operations, including end milling, face milling, and circular milling. And it is a versatile machine that can be used in various settings, making it a popular choice for both industrial and home users.

You can also find grinding mills here. You can read reviews of different grinding mills on the site and get an idea of which ones are the best. Whether you’re looking for a hand-operated mill or an electronic one, you’re sure to find what you’re looking for.

All About Milling Machines for Your Workshop Today

If you’re in the market for a milling machine, be sure to do your research and choose the model that’s right for your workshop.

With a lot of options available in the market, it becomes difficult to know where to start. But with a little know-how, you can find the perfect machine for your needs.

So, what are you waiting for? Go out and get the best milling machine for your workshop today!

Did you find this article helpful? Check out the rest of our blogs!