Mechanical engineering is one of the oldest, broadest, and most impactful branches of engineering. From the vehicles that transport us to the machines that manufacture everyday products to the HVAC systems that keep buildings comfortable, mechanical engineering influences nearly every aspect of modern life.

Yet despite its widespread presence, many people know little about what this discipline truly involves.

This comprehensive guide explores the subject from the ground up, providing a crystal-clear understanding of mechanical engineering fundamentals, essential concepts, practical applications, key tools, and emerging future trends.

Whether you’re a student, a professional exploring engineering paths, or simply curious about how machines work, this in-depth article will serve as your go-to reference.

Table of Contents

1. Introduction to Mechanical Engineering

Mechanical engineering is the science and art of designing, manufacturing, analyzing, and maintaining mechanical systems. It deals with anything that moves—or has the potential to move—under the influence of forces or energy.

As motion is an integral part of the physical world, mechanical engineering is foundational to virtually all engineering disciplines.

What Mechanical Engineers Do

Mechanical engineers typically:

- Design machines, engines, tools, and mechanical devices

- Analyze system performance (strength, efficiency, durability, safety)

- Select suitable materials for specific applications

- Design thermal and fluid systems

- Optimize manufacturing processes

- Work with automation, robotics, and control systems

- Solve complex engineering problems using mathematical and scientific principles

Mechanical engineering blends theoretical knowledge with practical problem-solving skills, making it both intellectually challenging and creatively rewarding.

2. History and Evolution of Mechanical Engineering

Mechanical engineering has existed in some form since humans began creating tools and machines. Its evolution can be divided into several key eras:

Ancient and Classical Eras

Early mechanical innovations include:

- The wheel

- Water wheels

- Lever, pulley, and screw

- Archimedes’ machines

- Early cranes and catapults

Civilizations like Egypt, Greece, China, and Rome laid fundamental mechanical principles, often without formal theory.

Renaissance and Early Science

During the Renaissance, major advancements occurred due to inventors like:

- Leonardo da Vinci (machines, flying devices, gears)

- Galileo Galilei (kinematics, dynamics)

- Isaac Newton (laws of motion, gravitation)

These scientific discoveries provided the foundation for classical mechanics.

Industrial Revolution

This was the turning point when mechanical engineering became a distinct discipline:

- Steam engines

- Textile machinery

- Locomotives

- Mass production

- Metalworking and machine tools

James Watt’s improvements to the steam engine revolutionized industries and transportation.

20th Century to Present

With electricity, internal combustion engines, computing, and advanced materials, mechanical engineering expanded into complex subfields like:

- Aerospace engineering

- Robotics

- Mechatronics

- Renewable energy

- Automation

- Nanotechnology

Mechanical engineering continues adapting to technological change, integrating software, electronics, and advanced materials.

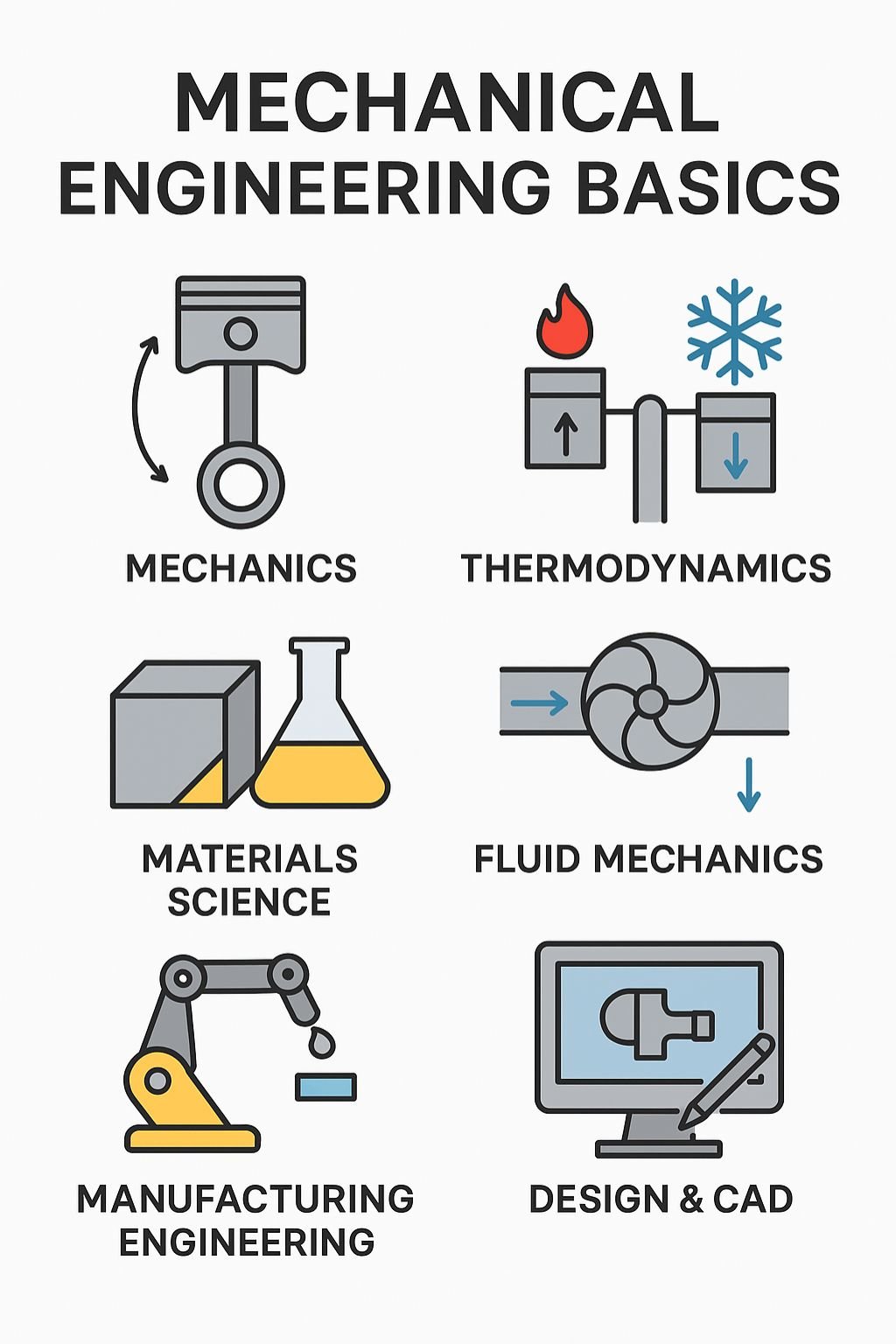

3. Core Areas Within Mechanical Engineering

Mechanical engineering is built on foundational sciences such as physics, mathematics, and material science. These foundational sciences branch into several core areas:

3.1 Mechanics

Mechanics is the study of forces acting on bodies and the resulting motion or deformation.

Branches of Mechanics

- Statics – study of systems in equilibrium

- Dynamics – study of moving bodies

- Kinematics – motion without considering forces

- Kinetics – motion considering forces

- Solid Mechanics – deformation and stresses

- Vibrations – oscillatory motion analysis

Mechanics is fundamental for designing structures, machines, and mechanical components.

3.2 Thermodynamics

Thermodynamics explains how energy is transformed, particularly heat and work.

Key Areas Include:

- Laws of thermodynamics

- Engines & refrigerators

- Energy conversion

- Combustion

- Power generation

Mechanical engineers use thermodynamics to design engines, power plants, HVAC systems, and even energy systems in vehicles.

3.3 Materials Science

Materials science deals with the properties, behavior, and applications of engineering materials.

Primary Engineering Materials

- Metals (steel, aluminum, titanium)

- Polymers (plastics, elastomers)

- Ceramics

- Composites

Mechanical engineers study material strength, elasticity, hardness, fatigue, and failure modes to select materials for specific design requirements.

3.4 Fluid Mechanics

Fluid mechanics studies liquids, gases, and how they behave under force and motion.

Applications Include:

- Aerodynamics (aircraft, automobiles)

- Hydraulics (pumps, turbines)

- Weather modeling

- Engine lubrication

- Cooling systems

Fluid mechanics is essential for designing efficient flow systems.

3.5 Manufacturing Engineering

This area focuses on processes that convert raw materials into finished products.

Common Manufacturing Processes:

- Casting

- Welding

- Machining (lathe, milling, drilling)

- Additive manufacturing (3D printing)

- Sheet metal forming

Manufacturing engineers ensure parts are produced efficiently, safely, and accurately.

3.6 Design and CAD (Computer-Aided Design)

Design is central to mechanical engineering—conceptualizing, analyzing, and refining mechanical systems.

CAD tools enable virtual prototyping, reducing time and cost.

Popular CAD Software:

- Creo

- SolidWorks

- AutoCAD

- CATIA

- Siemens NX

- Fusion 360

Design principles ensure systems are functional, safe, manufacturable, and efficient.

4. Fundamental Concepts Every Beginner Must Know

Understanding mechanical engineering basics requires familiarity with key principles.

4.1 Force, Work, and Power

Force – an influence that causes motion or deformation (Newton’s second law)

Work – force applied through a distance (W = F × d)

Power – rate at which work is done (P = W/t)

These fundamentals help engineers analyze machine performance.

4.2 Stress and Strain

Structural components must endure loads without failure.

- Stress (σ) – internal force per unit area

- Strain (ε) – deformation relative to original dimensions

Engineers use stress-strain curves to predict material behavior: elastic region, yield strength, ultimate strength, and fracture.

4.3 Kinematics and Dynamics

These concepts explain object motion:

- Velocity

- Acceleration

- Angular motion

- Projectile motion

- Rotational dynamics

Used in designing vehicles, machinery, and robotics.

4.4 Energy and Efficiency

Mechanical engineers calculate energy flows in systems:

- Mechanical energy

- Thermal energy

- Electrical-to-mechanical energy conversion

- System efficiency (output/input)

Improving efficiency reduces energy use and operational cost.

4.5 Heat Transfer

Heat transfer is crucial in processes where temperature changes occur.

Modes of Heat Transfer:

- Conduction

- Convection

- Radiation

Used in HVAC, engines, refrigerators, electronics cooling, etc.

4.6 Fluid Flow Basics

Fluid flow involves:

- Pressure

- Flow rate

- Laminar & turbulent flow

- Bernoulli’s equation

Engineers use these concepts to design pumps, pipelines, turbines, and ventilation systems.

5. Essential Tools and Software in Mechanical Engineering

Mechanical engineers use a variety of tools:

5.1 CAD and Simulation Tools

- SolidWorks (3D modelling, FEA)

- ANSYS (simulation, FEA, CFD)

- MATLAB (mathematical modeling)

- AutoCAD (2D design)

- COMSOL (multiphysics simulations)

These tools help visualize, analyze, and optimize components.

5.2 Measuring Instruments

- Vernier caliper

- Micrometer

- Dial gauge

- Thermocouples

- Pressure gauges

- Torque wrench

Used for precision measurement in labs and industries.

5.3 Manufacturing Equipment

- CNC machines

- Welding machines

- Lathe

- Milling machine

- Injection molding

Essential for prototyping and production.

6. Common Mechanical Engineering Processes

Mechanical engineering relies on various processes to create functional products.

6.1 Casting

Molten metal is poured into a mold. Used to create engine blocks, tools, and structural components.

6.2 Welding

Joining materials (usually metals) through heat or pressure.

Types include MIG, TIG, and arc welding.

6.3 Machining

Material removal process:

- Turning

- Drilling

- Milling

- Grinding

Used for precision components in automotive and aerospace.

6.4 Forming

Deforming materials without removing mass:

- Forging

- Rolling

- Extrusion

Popular for manufacturing large, strong components.

6.5 Additive Manufacturing (3D Printing)

Layer-by-layer fabrication used for:

- Rapid prototyping

- Lightweight aerospace components

- Medical devices

A rapidly growing area of engineering.

7. Mechanical Engineering in Everyday Life

Mechanical engineering is everywhere:

- Vehicles (engines, brakes, suspension)

- Home appliances (refrigerators, washing machines)

- Air-conditioning and heating systems

- Manufacturing of clothing, food, and goods

- Buildings and infrastructure

- Medical equipment

- Renewable energy (wind turbines, solar trackers)

Whether visible or hidden, mechanical engineering powers modern civilization.

8. Career Paths and Industries

Mechanical engineering offers diverse career options.

8.1 Core Engineering Roles

- Mechanical Design Engineer

- Manufacturing Engineer

- HVAC Engineer

- Automotive Engineer

- Maintenance Engineer

- Quality Engineer

- R&D Engineer

8.2 Interdisciplinary Roles

- Robotics engineer

- Mechatronics engineer

- Aerospace engineer

- Energy systems engineer

- Biomedical device engineer

8.3 Industries Hiring Mechanical Engineers

- Automotive

- Aerospace

- Oil & gas

- Power generation

- Manufacturing

- Defense

- Construction

- Electronics

- Robotics & automation

- Renewable energy

Mechanical engineering skills are transferable and in constant demand.

9. Challenges and Problem-Solving in Mechanical Engineering

Mechanical engineers tackle complex problems requiring analytical thinking.

Common Engineering Challenges

- Material failure

- Fatigue and wear

- Thermal expansion

- Efficiency losses

- Vibration and noise

- Fluid leaks

- High manufacturing cost

- Energy consumption

Engineers solve these using calculations, simulations, prototyping, and testing.

10. Future Trends Transforming Mechanical Engineering

Mechanical engineering is rapidly evolving.

10.1 Automation and Robotics

Robots increasingly handle manufacturing, surgery, agriculture, and logistics.

Mechanical engineers design robotic arms, joints, actuators, and sensors.

10.2 Artificial Intelligence & Digital Twins

Digital twins allow engineers to simulate real-world systems with precision, improving maintenance and design.

AI assists in:

- Predictive maintenance

- Optimization

- Fault detection

10.3 Renewable Energy

Mechanical engineers are at the forefront of:

- Wind turbine design

- Solar thermal systems

- Energy storage

- Electric vehicle engineering

10.4 Advanced Materials

New materials are enabling lighter, stronger, more efficient designs:

- Carbon fiber composites

- Shape-memory alloys

- Nanomaterials

- High-temperature ceramics

10.5 Additive Manufacturing

3D printing accelerates innovation by enabling:

- Custom parts

- Lightweight structures

- Rapid prototypes

- On-demand manufacturing

11. Conclusion

Mechanical engineering is a dynamic, diverse, and deeply influential field. From ancient tools to modern robotics, it has shaped human progress across centuries.

Mastering the basics of mechanical engineering—mechanics, thermodynamics, materials, fluid flow, and manufacturing—opens the door to countless career opportunities and innovations.

Whether powering cities, designing vehicles, optimizing manufacturing, or developing futuristic robots, mechanical engineers play a vital role in shaping our world.

Understanding these foundational concepts will give you a strong head start in exploring deeper topics and solving real-world mechanical challenges. Mechanical engineering is not just a discipline—it’s a mindset of logical thinking, precision, creativity, and continuous innovation.