Manufacturing is the backbone of the global industry. Whether it’s a smartphone, a car engine, a pharmaceutical product, or a simple household tool, every item around us is the result of a carefully designed manufacturing process.

Over the past few decades, manufacturing has transformed dramatically—shifting from labor-heavy methods to advanced automation, data-driven production, and highly optimized supply chains.

This comprehensive manufacturing guide is designed to help students, entrepreneurs, engineers, and business owners understand the essential elements of modern manufacturing.

From concept development and production planning to quality control and sustainable practices, this guide walks you through every important step.

Table of Contents

Understanding Manufacturing: What It Really Means

Manufacturing is the systematic process of transforming raw materials or components into finished goods. It involves people, machinery, workflows, and technology integrated into a structured production environment.

The primary goals of manufacturing include:

- Producing cost-effective, high-quality products

- Meeting customer and market demands

- Ensuring safety, compliance, and efficiency

- Reducing waste and optimizing resource use

- Maintaining consistent production output

Manufacturing can be as simple as assembling basic parts or as advanced as programming robots to perform nanometer-precision operations.

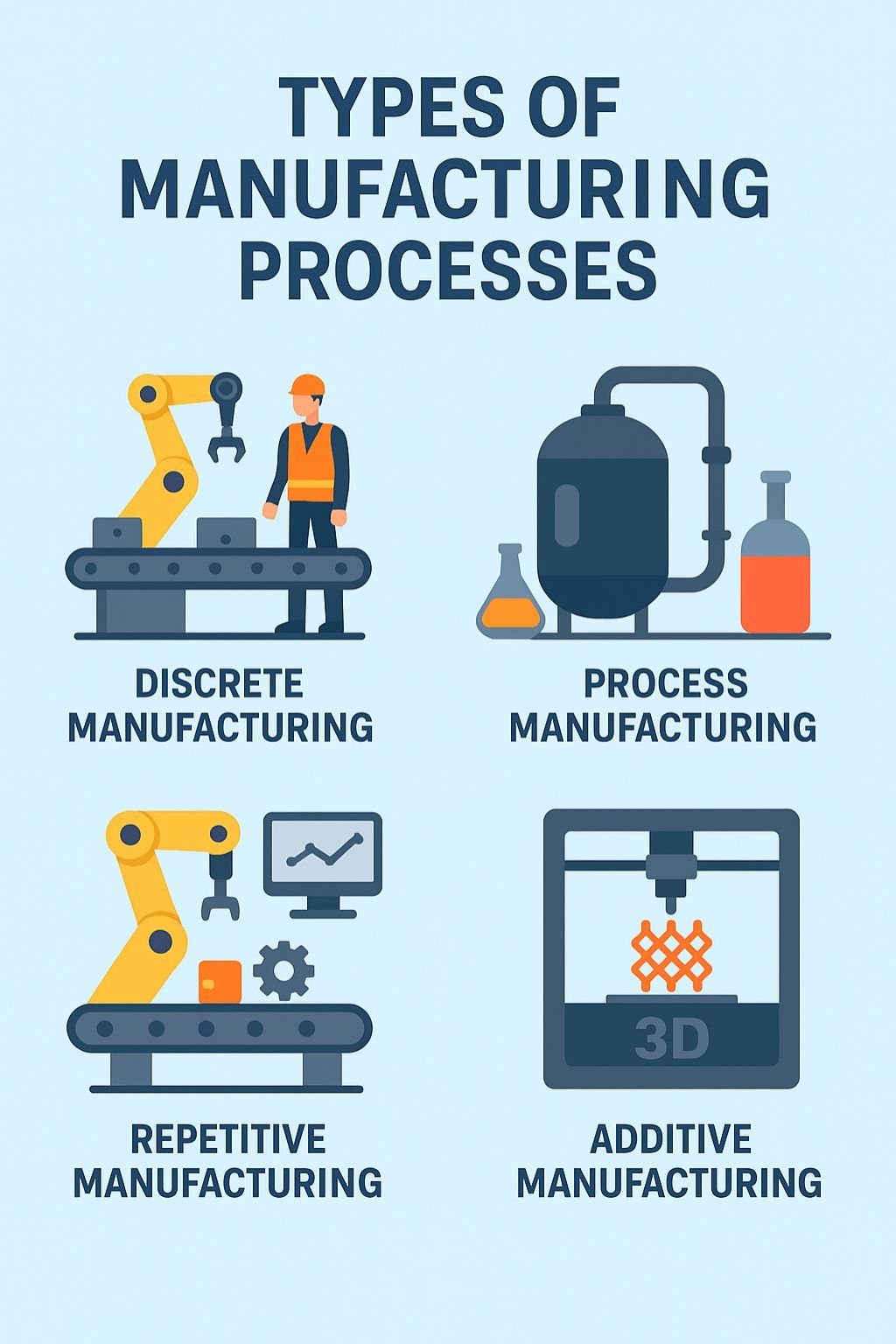

Types of Manufacturing Processes

Modern manufacturing involves a wide variety of processes. Understanding these is essential for determining the right method for your product.

1) Discrete Manufacturing

Used when products are made from individual, countable parts—e.g.:

- Automobiles

- Electronics

- Furniture

- Appliances

Products can be easily disassembled, and production runs may vary.

2) Process Manufacturing

Used for products that cannot be physically separated into components. Examples include:

- Chemicals

- Food and beverages

- Paints

- Pharmaceuticals

Process manufacturing often requires batch control and strict quality monitoring.

3) Repetitive Manufacturing

Large-scale, continuous production of the same product:

- Bottled beverages

- Consumer electronics

- Packaged food

It enables economies of scale and reduces per-unit cost.

4) Job Shop Manufacturing

Customized, small-batch production with high flexibility:

- Prototyping

- Custom furniture

- Specialized machinery parts

Ideal for unique products rather than mass production.

5) Additive Manufacturing (3D Printing)

A modern method where products are built layer by layer using:

- Plastics

- Metals

- Resins

This is ideal for complex geometries, low-volume production, and rapid prototyping.

6) Continuous Flow Manufacturing

Used in industries where products must be produced without interruption, such as:

- Oil refining

- Gas processing

- Large-scale chemical production

The process is highly automated and must run continuously to be cost-effective.

Key Stages of the Manufacturing Cycle

To understand manufacturing deeply, it’s essential to break down the stages from concept to final product.

1) Product Concept & Design

The first step involves:

- Understanding customer needs

- Creating preliminary sketches

- Developing 3D models

- Running simulations

Design determines functionality, cost, and manufacturability.

2) Material Selection

Choosing appropriate materials affects:

- Strength

- Durability

- Weight

- Cost

- Environmental impact

Material choices include metals, polymers, ceramics, composites, and more.

[PS: It is crucial to analyze material properties like tensile strength, hardness, toughness, malleability, and ductility to ensure they match product requirements.]

3) Process Planning

A detailed manufacturing roadmap includes:

- Required machinery

- Production workflow

- Workforce allocation

- Time and cost estimations

- Safety protocols

The goal is to define the most efficient way to produce the product.

4) Prototyping

A prototype allows manufacturers to:

- Test functionality

- Identify design flaws

- Validate user experience

Prototypes can be physical or virtual, depending on the complexity.

5) Manufacturing Execution

This stage involves actual production by using:

- Machines

- Tools

- Labor

- Automation systems

Efficiency and accuracy are crucial at this stage.

6) Quality Control & Testing

Quality assurance ensures products meet specifications through:

- Inspection

- Testing

- Statistical analysis

- Compliance verification

Poor quality can lead to returns, warranty claims, and reputational loss.

[PS: Testing methods such as tensile tests and impact tests help ensure the quality and durability of materials and final products.]

7) Packaging & Distribution

Finally, products are packaged to ensure:

- Safety

- Shelf appeal

- Compliance with regulatory standards

Then they move through logistics to reach customers.

Essential Manufacturing Tools & Technologies

Manufacturing has become technology-driven. Below are the most important tools in modern production environments.

1) CAD & CAM Software

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) are used for:

- Creating digital designs

- Precision machining

- Workflow automation

Tools include AutoCAD, SolidWorks, and Fusion 360.

2) CNC Machines

Computer Numerical Control machines automate cutting, drilling, and shaping tasks, offering:

- Precision

- Consistency

- Speed

Useful for metalworking and high-accuracy jobs.

3) Robotics & Automation

Robots perform tasks like:

- Assembly

- Welding

- Packaging

- Inspection

Robotics improves accuracy and reduces labor costs.

4) IoT & Smart Manufacturing

Sensors and connected systems enable:

- Real-time monitoring

- Predictive maintenance

- Automated quality analysis

Often part of Industry 4.0 environments.

5) 3D Printing

Used for:

- Rapid prototyping

- Custom components

- Simulation models

Reduces time-to-market significantly.

6) ERP & MES Systems

Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) help in:

- Production scheduling

- Inventory management

- Workflow tracking

- Compliance reporting

Centralized data leads to better decision-making.

Workforce and Skills Needed in Manufacturing

A successful manufacturing operation demands a skilled workforce with both technical and managerial capabilities.

1) Technical Skills

Workers need knowledge in:

- Machine operations

- Welding and fabrication

- Electric and mechanical repair

- Reading engineering drawings

- Robotics handling

Modern manufacturing requires multi-skilled operators.

2) Soft Skills

Important attributes include:

- Problem-solving

- Attention to detail

- Collaboration

- Analytical thinking

These skills help manage complex production tasks.

3) Training & Upskilling

With the rise of automation, continuous learning is crucial for:

- Robotics handling

- Data analytics

- Programming CNC machines

- Quality assurance systems

Companies that invest in training see improved productivity and reduced downtime.

Cost Factors in Manufacturing

Understanding cost is vital for profitability.

1) Raw Material Costs

Prices vary based on:

- Supplier location

- Market fluctuations

- Quality grades

Choosing the right supplier can save significant money.

2) Labor Costs

Includes:

- Wages

- Training

- Safety compliance

Automation can optimize labor distribution.

3) Machinery & Maintenance

Facility expenses include:

- Equipment installation

- Repairs

- Upgrades

Predictive maintenance reduces sudden breakdowns.

4) Overheads

General expenses include:

- Electricity

- Water

- Rent

- Security

- Insurance

Optimizing processes reduces overhead significantly.

Quality Control in Manufacturing

Quality control is not optional; it is essential.

– Types of Quality Control

- Incoming inspection: raw materials

- In-process inspection: ongoing production

- Final inspection: ready products

– Common Techniques

- Statistical Process Control (SPC)

- Six Sigma

- Lean manufacturing

- Total Quality Management (TQM)

– Industry Certifications

Depending on the product:

- ISO 9001

- ISO 14001

- GMP (Good Manufacturing Practices)

- CE marking

Certifications build customer trust.

Sustainability in Manufacturing

Sustainability has become central to modern production.

– Green Manufacturing Practices

- Using renewable energy

- Recycling waste

- Water conservation

- Energy-efficient machinery

– Circular Economy

Designing products so that components can be reused or repurposed.

– Eco-friendly Materials

Adopting biodegradable, recyclable, or low-impact materials is becoming a major trend.

Manufacturers investing in sustainability often experience:

- Lower operational costs

- Stronger brand reputation

- Better compliance

Future Trends in Manufacturing

Manufacturing is evolving rapidly with emerging technologies.

1) Industry 4.0

Smart factories using:

- IoT

- AI

- Big data

Allowing precise control over every process.

2) Autonomous Manufacturing

Self-regulating systems that adjust production without human intervention.

3) Artificial Intelligence Integration

AI helps in:

- Predictive maintenance

- Quality anomaly detection

- Inventory forecasting

- Production scheduling

4) Collaborative Robots (Cobots)

Robots designed to work alongside humans safely.

5) Advanced Materials

New materials like:

- Graphene

- Carbon-fiber composites

- High-entropy alloys

Enable stronger and lighter products.

Conclusion

Manufacturing is more than just producing goods—it’s a sophisticated system involving strategy, planning, technology, and skilled labor. As industries evolve, companies that embrace automation, digital transformation, and sustainability will lead the future of production.

Whether you’re starting a new manufacturing business, optimizing an existing operation, or simply learning the fundamentals, understanding the principles outlined in this guide will help you make informed decisions and stay competitive in a rapidly evolving world.