Whenever there is a need to evaluate the impact strength of a material like metal, ceramics, polymers, etc with the Charpy test, a Charpy impact test machine is used to perform the task.

It is worth noting that this kind of material test is quite critical in quality control.

Features of the Test

The test performed on a Charpy impact test machine possesses the following features:

- The test process is very fast.

- It is generally a comparative test.

- The specimen used in the testing process has the dimensions 55x10x10 mm.

- There is a notch machined on one face of the specimen.

- The notch machined on the specimen can either be a U-notch or a V-notch.

Importance of the Test

The test performed on the Charpy test machine is an affordable test to evaluate the impact toughness of various materials. It also helps in measuring or determining the notch sensitivity of materials.

In most cases, the test is performed on metals. However, other materials like ceramics, polymers, etc are also tested with it.

What is involved in the test performed on the Charpy impact test machine?

The test performed on a Charpy impact test machine to measure the impact strength of the material involves the following important things:

- There is a striker attached to the end of a pendulum. This striker is used to strike at the test piece.

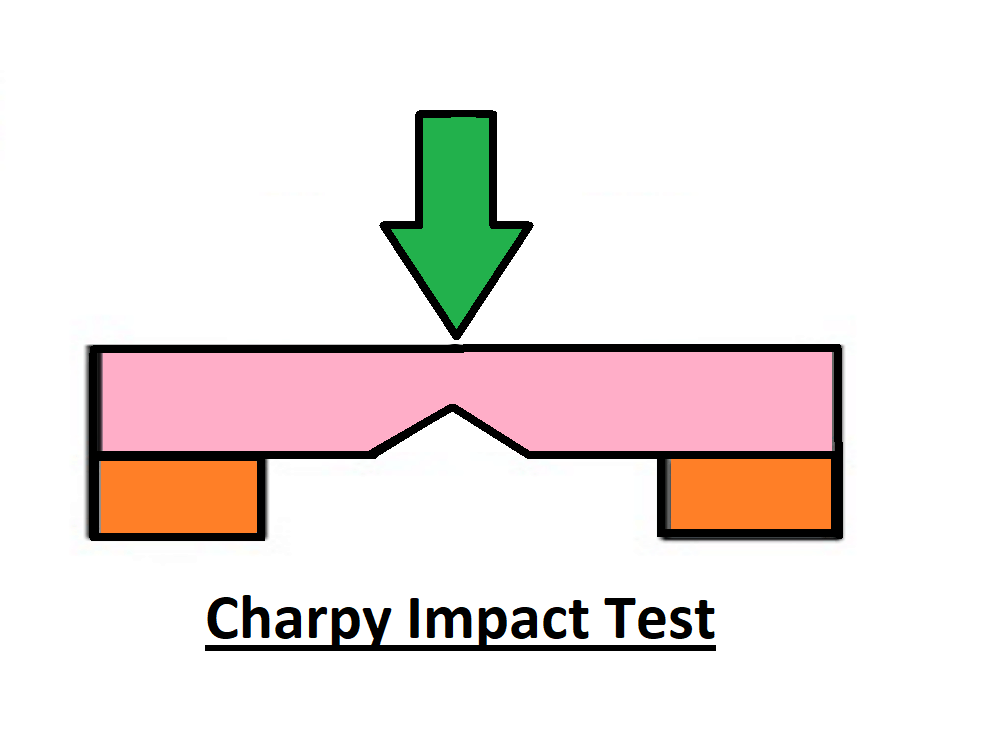

- The test piece or specimen is fixed at both of its ends. Once it is fixed, the striker is made to strike at the specimen’s face which is just opposite to the face having the machined notch.

- The impact strength or impact energy of the specimen is calculated on the basis of the difference between the height the striker can rise in the absence of the specimen and the height the striker has actually risen in the presence of the specimen after hitting or striking it.

That’s because this difference has taken place due to the energy absorbed by the specimen on being hit, proving it to be equivalent to the maximum energy the specimen can absorb before breaking.

Benefits of the Test

The test described in this article offers the benefits mentioned below:

- The test is simple and you can easily perform it.

- It is quite useful in judging product quality.

- The quality of new products can also be evaluated with the use of this test.

The Industry in Which Charpy Impact Test Machine is Used

Below I have listed some of the most important industries in which the Charpy impact test machine is used for quality evaluation:

- Ceramics manufacturing industry

- Oil & gas industry

- Aerospace industry

- Automotive industry

- Polymer manufacturing

- Power generation industry

Final Words

In 1900, Georges Augustin Albert Charpy invented this test, and is being used all over the world today. I hope the information provided above is enough for you to have a clear understanding of the topic.

Still, if you have any doubts, leave a comment below. I will try to respond as soon as possible. And, if you really liked this post, don’t forget to share it with others on social media, using the social media icons given under the post.

Below given are a few related articles that you can consider reading next: